Leverage 6063 T5 Aerospace-Grade Aluminum Extrusions for Construction Applications

Quality materials play a pivotal role in determining the durability, functionality, and overall efficiency of the end product. High-quality extruded aluminum tubes have emerged as a versatile and cost-effective option for constructing a wide array of industrial supply hardware due to their inherent properties including corrosion resistance, malleability, low weight, and h igh strength. Here’s how you can utilize extruded aluminum tubes effectively to build robust and efficient industrial supply hardware.

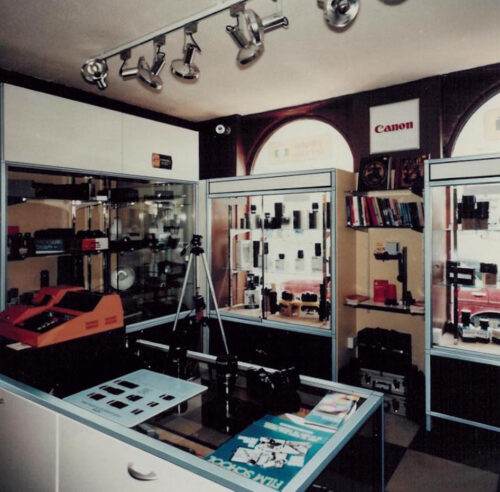

Photography store uses EZTube 6063 T5 aerospace grade aluminum extrusions and press fit fasteners connectors to build product displays, industrial supply hardware, construction equipment, and showcases

Understanding Aluminum Extrusions and Tubes

Extruded aluminum tubes are created through the extrusion process, wherein a billet of aluminum is heated and forced through a die to form the desired shape. This process allows for the creation of seamless, uniform tubes with precise dimensions and excellent structural integrity. Aluminum, being inherently lightweight, makes extruded aluminum tubes an ideal choice for applications where weight reduction is crucial without compromising on strength.

Key Advantages of Extruded Aluminum Tubes:

- Strength-to-Weight Ratio: Extruded aluminum tubes offer an exceptional strength-to-weight ratio, making them suitable for applications requiring structural integrity while minimizing weight.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, rendering extruded aluminum tubes highly resistant to corrosion even in harsh industrial environments.

- Malleability: Extruded aluminum tubes can be easily manipulated and fabricated into various shapes and configurations, allowing for intricate designs and customization according to specific requirements.

- Cost-Effectiveness: Compared to other materials such as steel, extruded aluminum tubes are generally more cost-effective, offering significant savings in both material and manufacturing costs.

Applications of Aluminum in Industrial Supply:

- Framework and Structural Components: Extruded aluminum tubes serve as the backbone for constructing frameworks, shelves, racks, and other structural components in industrial supply hardware. Their high strength ensures stability and load-bearing capacity, while their lightweight nature facilitates ease of handling and installation.

- Conveyor Systems: Aluminum tubes are widely used in the construction of conveyor systems for material handling in warehouses, factories, and distribution centers. Their corrosion resistance and smooth surface finish make them ideal for conveying various materials with minimal friction and wear.

- Piping and Tubing: Extruded aluminum tubes find applications in piping and tubing systems for conveying fluids, gases, and other substances in industrial settings. Their corrosion resistance and compatibility with different fluids make them suitable for diverse applications ranging from pneumatic systems to fluid transfer.

- Custom Fabrication: The malleability of extruded aluminum tubes allows for the creation of custom hardware components tailored to specific industrial requirements. Whether it’s specialized brackets, mounts, or fixtures, extruded aluminum tubes can be fabricated to precise specifications to meet the unique needs of different applications.

Best Practices for Utilizing Extruded Aluminum Tubes:

- Design Optimization: Ensure that the design of the industrial supply hardware optimally utilizes the properties of extruded aluminum tubes, such as their strength, weight, and corrosion resistance. Collaborate with engineers and designers to develop efficient and cost-effective solutions.

- Quality Assurance: Source extruded aluminum tubes from reputable manufacturers known for their quality and consistency. Conduct thorough inspections to ensure that the tubes meet the required specifications and standards for the intended application.

- Surface Treatment: Consider applying surface treatments such as anodizing or powder coating to enhance the durability, aesthetics, and corrosion resistance of extruded aluminum tubes, especially for applications exposed to harsh environments or corrosive substances.

- Precision Fabrication: Employ advanced fabrication techniques and equipment to achieve precise cutting, bending, and joining of extruded aluminum tubes, minimizing waste and ensuring dimensional accuracy in the final product.

Retail displays built using EZTube, the global leader in advanced commercial and industrial framing solutions

Aluminum extrusions and tubes offer a myriad of benefits for building industrial supply hardware, ranging from structural stability and corrosion resistance to cost-effectiveness and customization. By leveraging the unique properties of extruded aluminum tubes and adhering to best practices in design and fabrication, manufacturers can create high-quality and efficient industrial supply hardware that meets the demanding requirements of modern industrial applications. Order EZ Tube today from one of our official distributors to learn how extruded aluminum tubes, press fit fasteners, steel tubes, and stainless steel tubes are the perfect fit for you.