Rivet nuts, also called blind rivet nuts, threaded inserts, rivnuts, and rivets, are one of the most popular fastening solutions. Nearly ubiquitous in manufacturing, EZTube offers a size for every application.

These unassuming components play a pivotal role in establishing steadfast threaded connections, especially in materials where methods such as press-fit fasteners, face challenges. Let’s delve into the intricacies of rivet nuts, exploring their key characteristics, installation process, applications across industries, and the myriad benefits they offer.

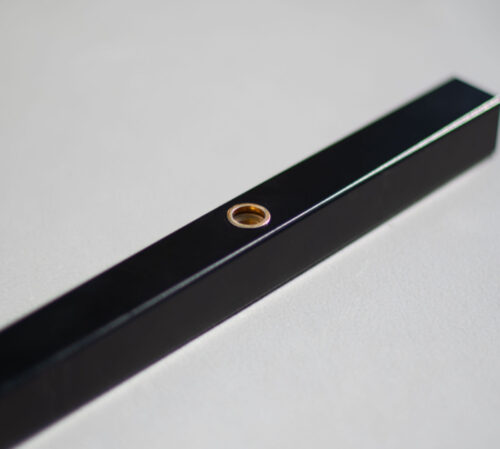

A rivet nut installed in a standard square EZTube aluminum extrusion

Key Characteristics of Rivet Nuts

- Blind Installation: A hallmark feature of rivet nuts is their ability to be seamlessly installed from just one side of the material. This attribute proves invaluable in scenarios where accessing the opposite side is either difficult or entirely impractical.

- Threaded Connection: Rivet nuts shine in their capability to create durable threaded connections. This enables the effortless attachment of bolts, screws, or other threaded fasteners, fostering secure and stable joints in diverse applications.

- Versatility: The adaptability of rivet nuts is truly remarkable. They find utility in various materials, including metals, plastics, and composites. This versatility renders them indispensable across a spectrum of industries, from automotive and aerospace to furniture assembly and do-it-yourself (DIY) projects.

- Enhanced Strength: Properly installed rivet nuts fortify materials with a robust and reliable connection. This strength allows them to withstand vibrations, shear forces, and other stresses, making them ideal for applications demanding a resilient fastening solution.

Riv Nut Installed

Installation Process

- Drilling: Begin by drilling a hole into the material to accommodate the rivet nut.

- Insertion: Gently insert the rivet nut into the drilled hole.

- Compression: Utilize a specialized tool to compress the rivet nut, inducing deformation and causing it to grip the material tightly.

- Threaded Connection: With the threaded portion securely embedded, the rivet nut is now prepared to receive bolts or screws, creating a reliable threaded connection.

Applications Across Industries

Rivet nuts find widespread applications across diverse industries and projects, including:

- Automotive: Essential for attaching components and securing panels.

- Construction: Ideal for joining metal sheets and creating threaded holes in structural elements.

- Aerospace: Commonly employed in aircraft assembly for lightweight and durable fastening.

- Furniture: Used to establish robust connections in wooden or metal furniture pieces.

Benefits of Rivet Nuts

Due to their extremely versatile nature, rivet nuts offer a plethora of benefits which include, but are not limited to:

- Accessibility: Suited for applications where accessing the opposite side is challenging.

- Time Efficiency: Installation is quicker compared to traditional threaded inserts.

- Strong and Reliable: Creates a robust threaded connection, ensuring enduring stability.

Let EZTube Do the Work for You

At EZTube, we don’t just sell rivet nuts. We offer complete installation and fabrication services, as well. Let us do all of the work–you’ll get a complete, ready-to-assemble kit ready to go.

Over decades, rivet nuts have proved themselves as indispensable components of manufacturing, providing a secure and efficient solution for creating threaded connections across a myriad of materials and applications. Their versatility, strength, and ease of installation position them as a preferred choice for professionals and DIY enthusiasts alike, unlocking a world of possibilities in the realm of fastening solutions.