Aluminum, a versatile and lightweight metal, is an integral part of our daily lives, even if we might not always realize it. Modern advancements in manufacturing have made products like anodized aluminum available to all markets.

From the frame of your car to the foil in your kitchen, aluminum’s applications are diverse and essential, and is becoming even more important in technically advanced applications. In this article, we will break down the fundamentals of this amazing elemment; we will learn what it is, explore its chemical composition, common uses, manufacturing processes, its historical significance, and we’ll also discuss a specialized aerospace-grade variant – 6063 T5 aluminum, exclusively employed by EZTube for anodized and powder coated extrusions.

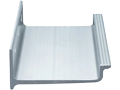

Light Wall Installation Built Using EZTube EZTube, the global supplier of commercial and industrial framing solutions. 6063 T5 aerospace aluminum square tube being used for a light wall artistic installation display

Understanding Aluminum: From Composition to Applications

Chemical Composition and Characteristics

Aluminum, symbolized as Al on the periodic table, is a silvery-white, soft, non-magnetic metal. It’s remarkable for its low density and ability to resist corrosion, making it an ideal material for various applications. Chemically, aluminum is a reactive metal and forms a strong oxide layer when exposed to air, preventing further corrosion.

Common Uses

Aluminum’s versatility makes it ubiquitous in modern life. It’s widely used in transportation (cars, airplanes, bicycles), packaging (cans, foil), construction (windows, doors, siding), electrical appliances, and even in space technology. Its low weight-to-volume ratio makes it essential in high-tolerance applications like aerospace engineering and transportation, where weight saving is crucial to improved fuel efficiency and a reduced carbon footprint.

Manufacturing Process

The primary raw material for aluminum is bauxite, a clay-like soil which occurs in nature and is found in tropical and subtropical regions. Through an energy-intensive process called the Bayer Process, bauxite is refined into alumina. Electrolytic reduction of alumina in molten cryolite yields pure aluminum. It can then be processed into various shapes and sizes through techniques like extrusion, extruding square tube, forging, or casting, depending on the intended use. For EZ Tube, a highly specialized variant known as 6063 T5 is extruded, which creates a high-quality square tube that can be used in advanced industrial solutions, construction, framing, industrial supply, heavy equipment manufacturing, wholesale, distribution, commercial and consumer applications, room dividers, shelving, desks, furniture, artwork, and more. The extensive use cases for extruded aluminum tubing are endless.

Historical Significance

The element’s history is fascinating. In the 19th century, it was considered a precious metal, more valuable than gold. In 1852, aluminum was priced at $545 per gram, which is roughly equivalent to $1.6 million per kilogram today. However, advancements in electrolytic reduction methods, primarily pioneered by Charles Martin Hall and Paul Héroult, led to a significant drop in production costs, making it accessible to various industries and consumers.

6063 T5 Aerospace-Grade Aluminum and EZTube

6063 T5 Aluminum: This alloy is a variation of 6063 aluminum, which is particularly well-suited for extrusion processes. The ‘T5’ designation signifies that it has been artificially aged to achieve high strength. 6063 T5 aluminum possesses excellent corrosion resistance and weldability, making it ideal for aerospace applications where durability and lightweight properties are paramount.

EZTube’s Exclusive Choice: EZTube, a leading name in advanced, high-precision industries, exclusively employs 6063 T5 aluminum in its products, which are all available in a beautiful anodized finish or various high-quality powder coated finishes. These choices are not arbitrary. EZ Tube has been committed to providing its customers with the highest quality metals, composites, ceramics, and nylons available for over three decades. The high strength-to-weight ratio of this alloy is crucial in technically advanced environments like aerospace and others, where reducing weight without compromising structural integrity is a constant goal. EZTube’s commitment to using this space-age material in its extruded aluminum square tubing, particularly for anodized and powder coated finishes, ensures the safety and reliability of its products, meeting the stringent standards of the industrial supply, commercial, automotive, construction, aerospace, research, solar, and scientific industries, and beyond.

6063 T5 aerospace aluminum used by EZTube for aluminum extrusions. EZ Tube is the global leader in advanced commercial and industrial framing solutions, supply, advanced metals, composites, and distribution.

Aluminum’s journey from being a precious metal to a widely accessible material is a testament to human ingenuity and innovation.

The elements applications, ranging from everyday items to cutting-edge aerospace technology, highlight its importance in our modern world. With specialized variants like 6063 T5 aerospace-grade aluminum, companies like EZTube continue to push the boundaries of what this remarkable metal can achieve, shaping the future of genetic, automotive, and aerospace engineering–and more. At EZ Tube, we’ve only just begun our journey towards making the world more technically advanced place for all of humankind.